Top loading station "Single-vat" type.

For loading trucks and railcars tank

Manual folding stairs with body guard protection.

The entire structure is balanced by 2 gas actuators, the stairs are available in 2 versionss :

- 1m steps length with a 2m nacelle width

- Or 2m steps length with a 3m nacelle width

Fix footbridge dimension 1600x1600 on central foot.

Loading arm support.

Loading arm DN80 (3") or DN100 (4").

Possibility of pneumatic control (folding stairs & arms).

All painted or galvanized depending on customers specifications.

Top Loading station "Multi-vat" type.

For loading trucks and railcars tank

Adjustable folding stairs of 2 to 12m length. Balanced by monobloc counter point, the rotating structure is mounted on platform with bearings. The back protection is independently balance from the stairs and is link to it with a double connecting rodinsuring a contact with the dome of the truck or wagon and offering a maximum protection to the operator.

The control can be manual effortlessly or hydrau-pneumatic with hydraulic locking in all position.

Possibility to install a retractable gate to adjust the length of the protection in the case of a small road tanker.

Top Loading station "Multi-vat" type

For any type of loading :

- Large and small road tankers

- Wagons

- Iso container on platform

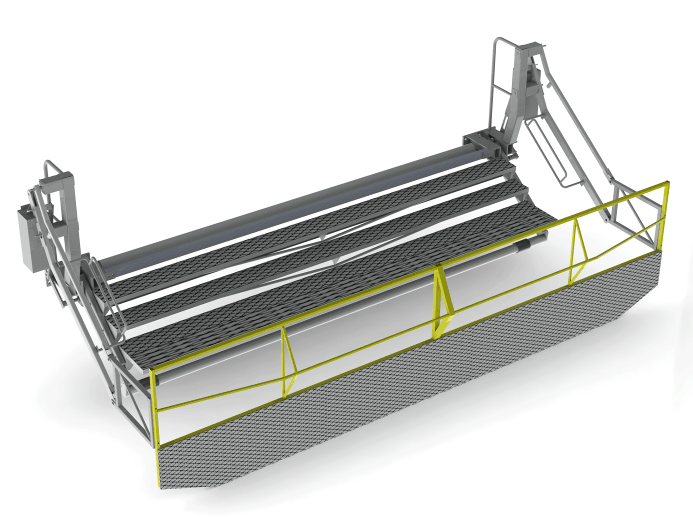

The lifted floor : For an optimum security !

Designed and built to access on a single platform all types of trucks.

(Small and big carriers, Wagons and Iso container on platform)

CERTI’s engineers have identified and listed all the possible hazardous situations of a vertical loading in order to provide an apparatus with an optimum security level.

Since its construction, the equipment has evolved and today we are able to guarantee a high level of security.

Principle of operation :

The operation is fully automatic and failsafe.

From the fix bridge, the operator presses the down button.

- The platform come closer to the vehicle to be loaded

- It is possible to block the platform before contact with the vehicle (if steel tank or weighting at the loading dock)

- If the tank to load is strongly inclined, the operator presses inclination (L or R) and the lift adapts to this situation (catching up to about 30 cm tilt forward or backward).

- The operator then adjusts the rear guard that comes into contact with the vehicle.

- Then it sets the railing Left and Right side.

- Once the loading is complete, the operator presses the button up :

- The platform is in the upper position, the side railings are close to the size of the container (approx 6m)